EQUIPMENT

In the field of OEM (Box Building) services, as a company with decades of experience in one-stop electronic manufacturing services (Electronic Manufacturing Services), it has mature PCBA manufacturing technology, product assembly, complete supply chain system, and professional The technical team and strictly business process make us competent enough for customers' electronic product OEM tasks, give full play to our core advantages in this field, and continue to create value for customers.

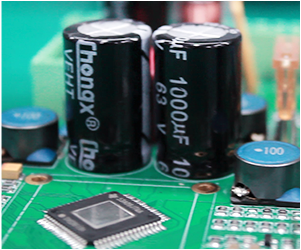

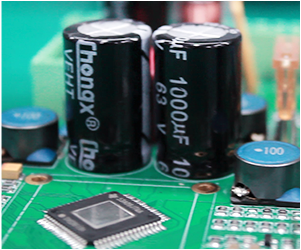

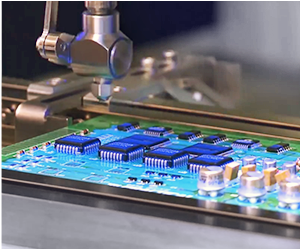

Starting from the circuit board (PCB) production process, JLH TECHNOLOGY CO.,LTD strictly follow customer requirements, strictly select high-quality plates and high-precision production equipment, 100% AOI testing, flying probe and test frame testing to ensure a relatively high level of yield; We have established long-term and stable cooperative relationships with well-known brand agents and high-quality source suppliers in the procurement of components and plastic parts, silicone components, hardware accessories, and series of wiring harnesses. We have the bargaining power for bulk purchases and ensure the stability of delivery. In the SMT patch and DIP plug-in link, we use Yamaha (YAMAHA) high-precision high-speed placement machine and 10 temperature zone reflow soldering, wave soldering, X-RAY, optical AOI equipment to ensure the reliability of the PCBA soldering process quality. In terms of program burning, we can provide online burning and offline burning, and support IC burning and testing of packaging such as tube/tray/reel. Finally, carry out product module and accessory assembly (Box Building) and test, seamlessly assemble PCBA circuit board with related molds and accessories, and perform FCT function test to provide customers with a complete ODM solution. In the entire manufacturing process, we have strict IQC incoming inspection positions, IPQC process inspections and OQA factory inspections to ensure that no defective products are produced or discharged. In addition, we will provide timely response and feedback services according to the customer's product design plan and production process. In order of process sequence, the specific business segments are as follows:

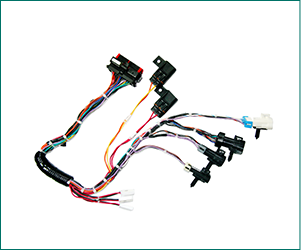

1. JLH TECHNOLOGY CO.,LTD supply chain resources, procurement of parts and components

We integrate upstream and downstream electronics manufacturing companies in multiple fields to establish a long-term cooperative relationship with high flexibility and short delivery time. Our company is also equipped with professional structural engineers, electronic engineers, and purchasing engineers to strictly select high-price materials for customers, and can provide customers with: plastic parts, hardware parts, silicone parts, electronic wiring harnesses, electronic components and other materials selection and procurement service.

Electronic wiring harness

|

Electronic Components

|

Silicone parts

|

Plastic parts

|

Custom Metal Parts

|

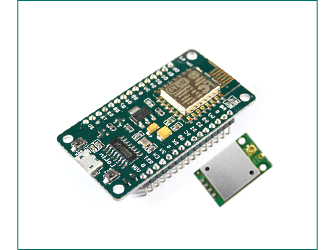

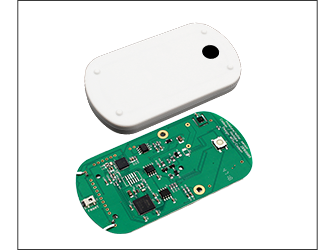

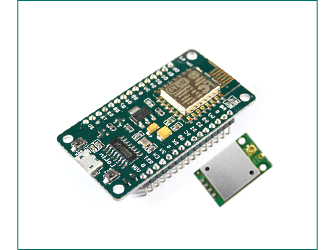

Modules

|

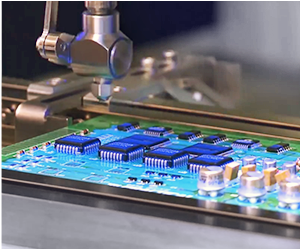

2. One-stop PCBA assembly service

JLH TECHNOLOGY CO.,LTD has 12 years of manufacturing experience in PCB manufacturing, component procurement, SMT chip processing and test assembly. It is also a one-stop electronics manufacturing service provider for PCBA assembly. You only need to send us the PCB gerbers, BOM bill of materials and special process requirements, and you can produce PCBA products without any worries. And the fastest proofing (including PCB, purchased materials, patch plug-ins, testing) in the fastest 3 days, the engineering cost is at least about 20% lower than the market price. PCBA assembly services mainly include the following aspects:

PCB Manufacturing |

SMT

|

DIP

|

Functional Test

|

Programming |

Conformal coatings |

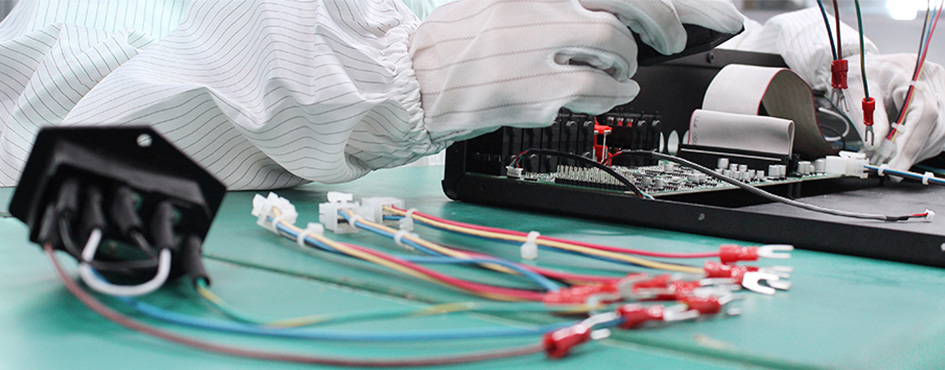

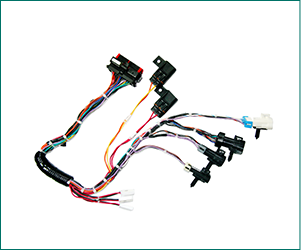

3. Wiring harness and connector assembly

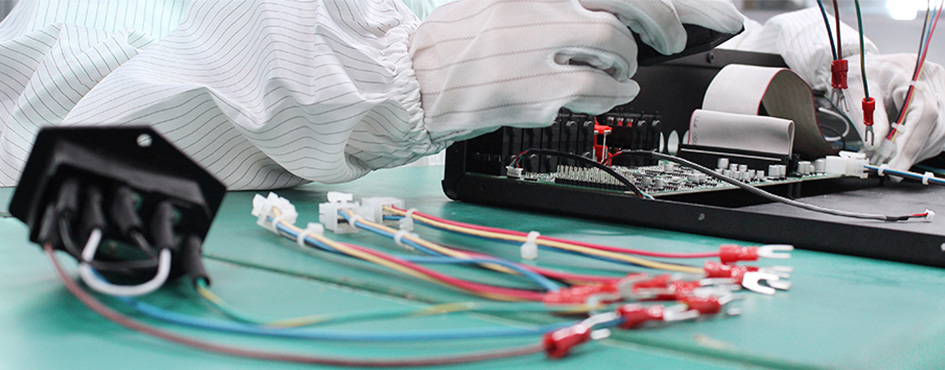

We have a professional engineering and assembly team to assist in design and assembly support. From PCBA to connector welding and wiring harness assembly, we build a complete set of production plans and product overall test plans, which greatly saves product turnover and logistics costs. Thereby shortening the product delivery time, greatly enhancing the competitiveness of the product.

Whether your requirement is a single-ended wire or a complete harness with connectors, switches and fuses, you can be sure that we are confident to provide one-stop high-quality services. Common connectors or wiring harnesses are: 10/100/1000 Base-TX modular jack, magnetic RJ45 jack, modular jack + USB, modular jack + HDMI, IP camera connection cable, SFP connector, DVI Series, DC socket series, HDMI series, FPC series...

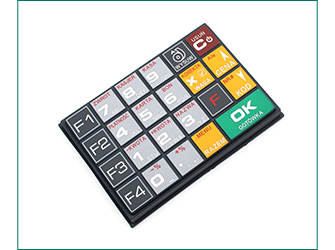

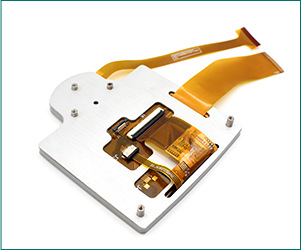

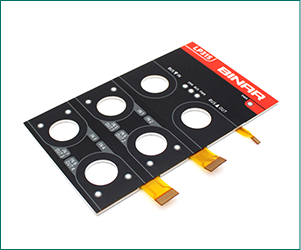

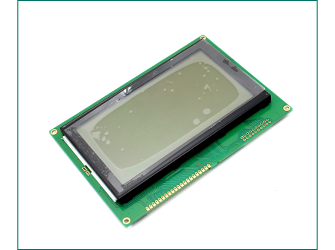

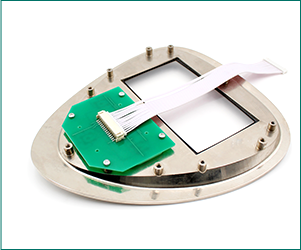

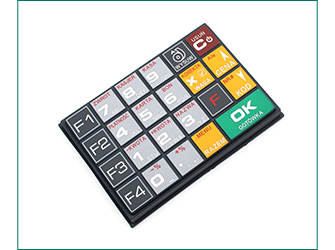

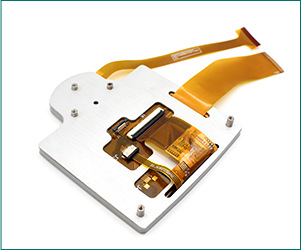

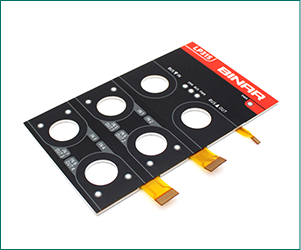

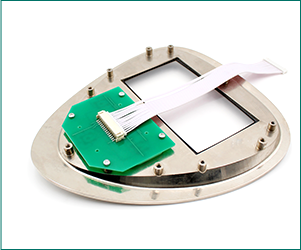

4. The man-machine interface assembly

JLH TECHNOLOGY CO.,LTD have provided human-machine interface solutions and products for many fields, including: consumer electronics, healthcare and beauty industry, instrumentation industry, network communication industry, rail transit, industrial control, automation control, machinery Equipment, household appliances and other fields. In particular, the healthcare and beauty industry has high requirements and strict industry standards for product safety, reliability, and durability. We adopt ISO13485 medical system standards to implement production, and have passed ISO13485, ISO14001, ISO9001 and other authoritative certifications.

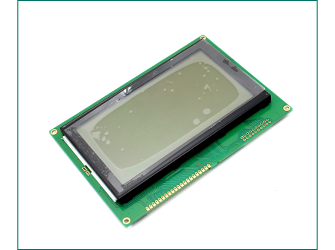

In addition to human-machine interface assembly and testing, we also provide human-machine interface component manufacturing, design, and supply chain resources, including: capacitive touch membrane switches, rigid, flexible membrane switches, backlit membrane switches, antibacterial membrane switches, silicone key switches, Backplane membrane switch, touch screen, membrane panel, metal bracket, LCD, etc.

Various membrane switches (can be designed and manufactured)

|

Silicone buttons (design, mold opening, and purchase on behalf)

|

Rigid and flexible switch circuit board (design and purchase on behalf)

|

Thin film panel (can be designed and manufactured)

|

LCD/LED, etc. (provide supply chain resources)

|

Metal and plastic parts (supply chain resources, procurement)

|

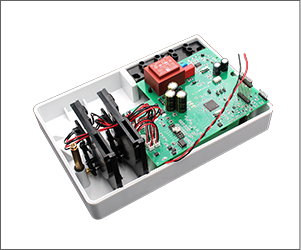

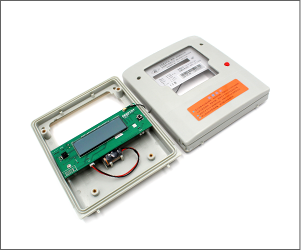

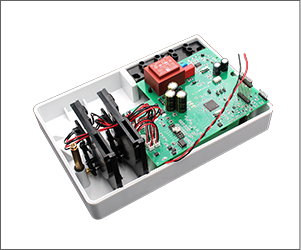

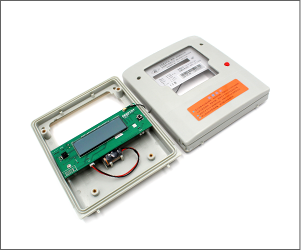

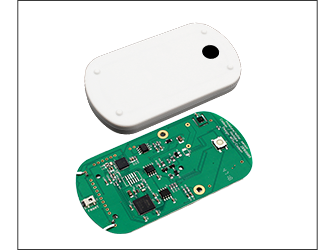

5.Product assembly assembly

Electronic product assembly services, involving industrial controllers, medical electronics, Internet of Things modules, electronic and electrical equipment, etc., assemble PCBA circuit boards, human-machine interfaces, shells, wiring harness connectors, and other modules that have been produced and tested together to form a package A complete set of products is delivered to end customers for use. As an important part of EMS electronic manufacturing, electronic assembly business has many processes and complex processes. Therefore, process control and quality control are particularly important in finished electronic products. Our company has passed the ISO9001:2015 quality management system and ISO13485 medical device management system. During the PCBA assembly process, we strictly implement relevant SOP operation standards, station self-inspection, QC full inspection, QA online sampling inspection, OBA sampling inspection before shipment, etc. At the same time, the barcode management system is adopted to effectively trace and register the good products and the defective products, and achieve the ideal goal of the assembly straight-through rate and the customer quality random inspection pass rate.

Over the years, JLH TECHNOLOGY CO.,LTD have provided one-stop electronic product assembly services for customers in various industries, including: industrial, energy, medical, transportation, communications, home appliances and other fields. The following is part of the electronic assembly display:

Coin machine

|

New Energy Management System

|

Smart gas meter

|

Automatic blood analyzer

|

Building fire call machine

|

Water leak alarm

|

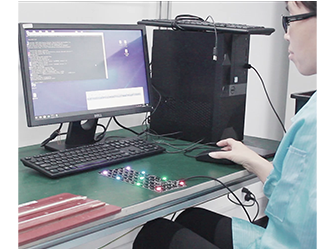

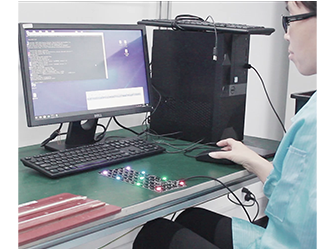

6. Product testing

Product testing is mainly divided into functional testing and aging testing. Product function testing is to verify the functions of the product in accordance with the test plan, test work instructions and test fixtures provided by the customer. According to the functional test cases, test item by item to check whether the product meets the functions required by the customer. The aging test item is a process of simulating the various factors involved in the actual use conditions of the product to carry out corresponding conditions to strengthen the experiment on the aging of the product. The experiment is mainly for plastic materials. The common aging mainly includes light aging, damp heat aging, and hot air. Ageing. Aging tests have become an indispensable process in end product manufacturing and quality control. They can help you reduce the risk of premature product failure.

Aging Test

|

Function Test

|

7. Protection and packaging

Whether it is material preparation before launch, or the production process and shipment, we attach great importance to product protection to prevent products from physical damage during turnover and handling. During the production process, we will use anti-static packaging to protect the appearance of the product while also avoiding certain sensitive electronic components from being damaged by static electricity.

Material protective packaging before production

|

Production process and turnover protective packaging

|

Shipping packaging

|

We will set up a dedicated project leader and project manager to track your electronic product ODM and OEM foundry projects throughout the process, and be responsible for all-stage control of early technical requirements discussion, filing, mid-term Beta testing, proofing, regression modification, finalization, batching, etc. , Implement in accordance with the project's expected timetable, provide you with satisfactory electronic product ODM and OEM foundry services, and strictly control the quality of the entire Box Building process.

-

![]()

EN

EN

Whatsapp 0086 755 29438407

Whatsapp 0086 755 29438407 Mail info@ALPCB.com

Mail info@ALPCB.com  Tel 0086 755 29438407

Tel 0086 755 29438407